Diesel generating plants have an important role in power plants as well as in industries and commercial installations to meet continuous and emergency standby power requirements for day-to-day use.

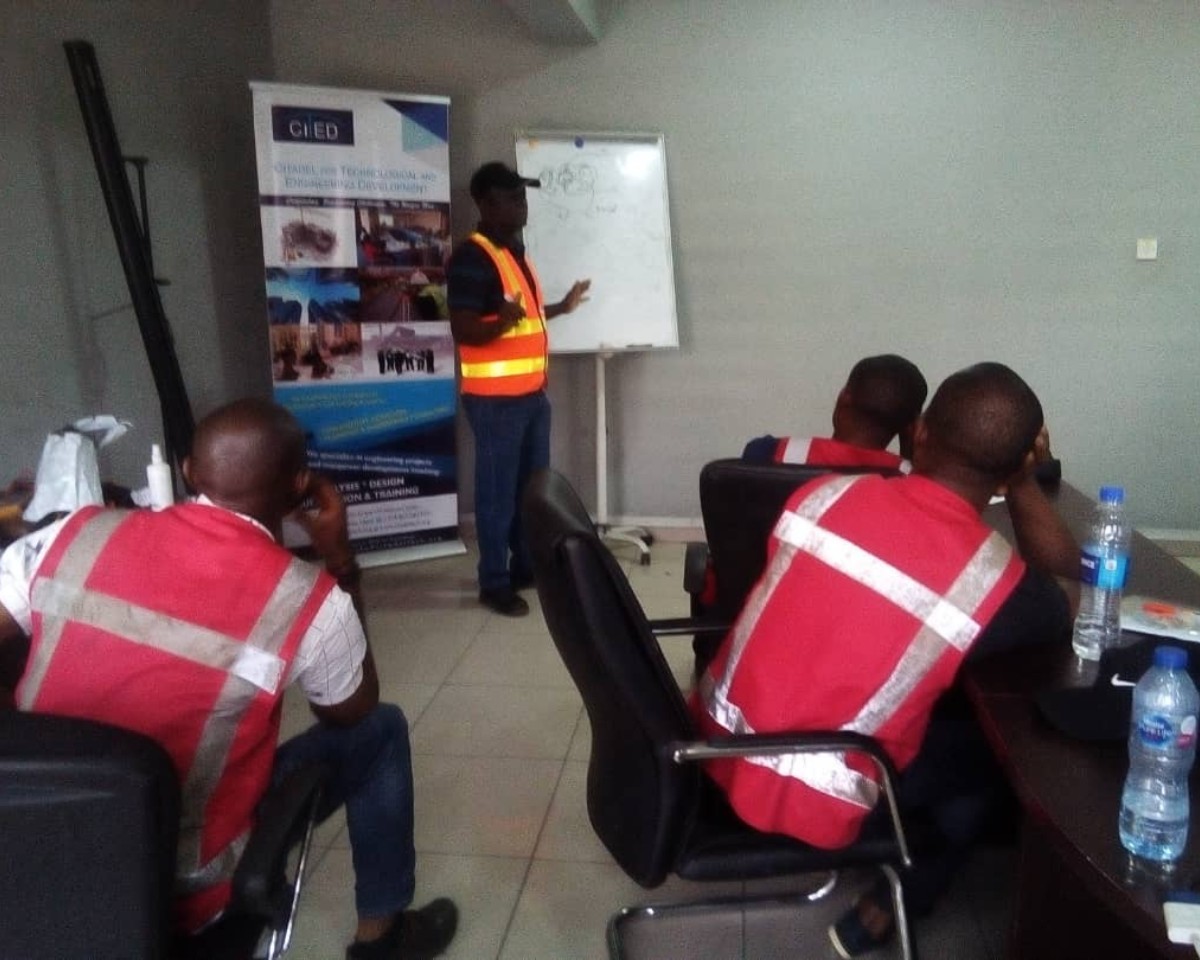

DIESEL GENERATORS: OPERATIONS, MAINTENANCE, CONTROL, TESTING AND TROUBLESHOOTING

Diesel generating plants have an important role in power plants as well as in industries and commercial installations to meet continuous and emergency standby power requirements for day-to-day use. A good knowledge of basic operation principles, layout requirements, associated components and maintenance practices for diesel power plants help the career development of many engineers and technicians in today’s demanding world. Whatever your role in industry – designer, purchase engineer, installation contractor or maintenance engineer, a solid knowledge of diesel power plants is always useful. This workshop is designed to familiarise you with various aspects of diesel generating power plants for practical application.

Examples will be taken from various industrial standard practices regarding the construction, layouts, application and maintenance procedures followed for reliable and trouble free operation of diesel power plants. The various tests to be conducted during commissioning and maintenance checks to ensure proper and long term operation of diesel power plants will also be covered in the workshop.

Some essential systems such as fuel oil layouts, lube oil requirements and control circuitry will also be discussed.

INTRODUCTION

- Power generation methods

- AC power vs DC power

- Single phase and three phase AC power • Prime movers

- Power plant types

- Diesel power plants

- Advantages of diesel power generation

- Engine types

DIESEL TECHNOLOGY AND CLASSIFICATIONS

- Basic engine processes

- Reciprocating engines

- Spark ignition engines • Diesel engines

- Dual fuel engines

- Speed classifications • Service classifications

- BASIC ENGINE DESIGN AND RATINGS

- Design characteristics and formulas • Turbo charger

- Ambient conditions

- ISO ratings

- Performance and efficiency • Efficiency enhancements

- Engine speed

- Fuel combustion methods

FUEL OIL SYSTEMS AND LAYOUTS

- Crude oil

- HSD, LDO and heavy fuels

- Economics of fuel selection

- Pressure and temperature characteristics • Viscosity

- Specific heat and temperature

- Specific fuel consumption

- Fuel filters and heaters

- Fuel nozzles and igniters

- Emission control

- Storage requirements

- Typical fuel system layouts and

- components

LUBE OIL SYSTEMS

- Lube oil specification

- Lube oil consumption in diesel engines • Typical lube oil system layouts

- Viscosity and temperature

- Lube oil filters and heaters

GENERATORS

- Principle of operation

- Major components (field coils, commutator, DC output, regulator, armature, rotating diodes)

- Generator types

- Low voltage and medium voltage generators

- Typical circuitry

- Load types and generator sizing

- System grounding methods

- Faults and protection

- Performance evaluation and testing

DIESEL GENERATING SETS

- Coupling requirements

- Skid mounting

- Layout requirements

- Paralleling of multiple DG sets • Standard control panels

- Interconnections

OTHER COMPONENTS

- Starting methods

- Starting characteristics

- Battery sizing

- Step load requirements

- Standby requirements

- Auto start and auto transfer schemes • Auto transfer switches

DG PLANT LAYOUTS

- Industrial applications

- Power generation plant applications • Single and multiple sets

- Fuel storage requirements

- Air intake system

- Exhaust system

- Auxiliary power requirements

- Typical power schemes

TESTING AND COMMISSIONING

- Factory tests

- Pre-commissioning checks and tests • Performance monitoring

- Fuel and lube oil consumption checks

OPERATION AND MAINTENANCE

- Safety requirements

- Operation monitoring based on applications

- Maintenance techniques

- Spares and inventory management • Inspection

- Engine overhaul and repair

- Troubleshooting